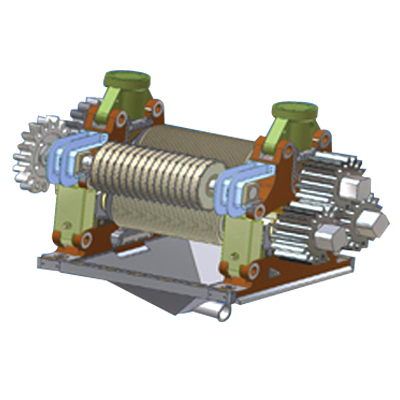

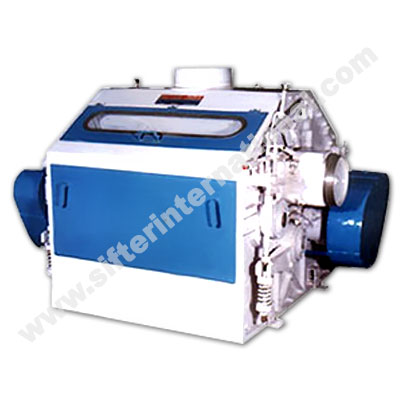

Product Profile of Heavy-Duty Four Roller Mill

ThyssenKrupp Industries India Pvt. Ltd. offers Heavy-Duty Four Roller Mill. ThyssenKrupp Industries India Pvt. Ltd. supplies Sugar Plants & Machinery, Open Cast Mining & Bulk Material Handling Systems, Cement Plants & Machinery and Industrial Boilers & Power plants. The major benefit of the Heavy-Duty Four Roller Mill is an increase in crushing capacity with a marginal increase in cost and power consumption. The Heavy-Duty Four Roller Mill has drive options like Hydraulic, Electric or Steam Turbine.

Key Features of Heavy-Duty Four Roller Mill

- Robust heavy-duty housing design for improved rigidity and stability to handle higher throughput

- The pin-type construction makes it easy to assemble or dismantle. The side caps provide a platform for rapid emergency maintenance

- The fourth roller rests directly on the main housing and is provided with bolting and locking arrangement to allow close setting

- The drive to the fourth roller is directly from the top roller through heavy and long teeth pinions

- Vertical and horizontal adjustments are made possible by machined packing plates and specially designed bearing housings

- Most suitable for cane feed with vertical Donnelley chute

- Higher capacity with no extraction loss

- No mill-gripping problems even with too fine a preparation, higher imbibitions rates up to 300% with high temperature

- Ease in setting adjustments, assembling and dismantling, due to the unique simplicity of design