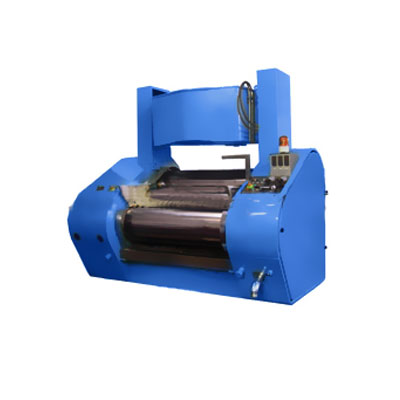

Product Profile of Hydraulically Operated Tri-Roller Mill

Hydraulically Operated Tri-Roller Mill is suitable for grinding and dispersing ointment or high viscosity materials with high requirement of fineness. The Tri-Roller Mill achieves required grinding effect by the friction and crashing among the three tilt rollers rotating at different speeds. The Tri-Roller Mill is equipped with emergency brake button to prevent equipment damage caused by foreign matter dropped into. Hydraulically Operated Tri-Roller Mill is used in coating and paint, printing inks, dye and pigment, food and flavours industries.

Applications of Hydraulically Operated Tri-Roller Mill:

Coating and paint

Printing inks

Dye and pigment

Food and flavours industry

Key Features of Hydraulically Operated Tri-Roller Mill

- Suitable for grinding and dispersing ointment or high viscosity materials with high requirement of fineness

- Achieves required grinding effect by the friction and crashing among the three tilt rollers rotating at different speeds

- Equipped with emergency brake button to prevent equipment damage caused by foreign matter dropped into

- The hydraulic system controls and regulates the clearance between the rollers to achieve the desired final fineness and production output

- The roller is a casting of special hard alloy and ceramic materials are optional.