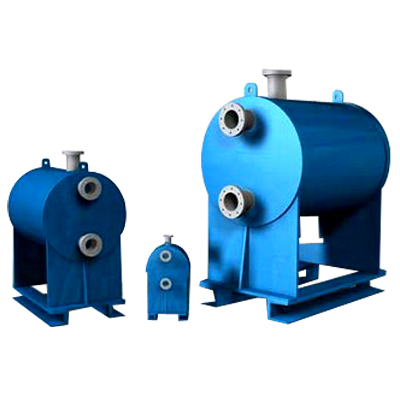

Product Profile of Welded Shell & Plate Heat Exchanger

Tranter Phe Division supplies Welded Shell & Plate Heat Exchanger. Tranter Phe Division offers diverse types heating equipments. Welded Shell & Plate Heat Exchanger is ideal for various sectors like- motor vehicle, chemicals, power plant, co -generation application, pulp and paper application, sugar application, marine, power generation, oil and gas industry etc. Welded Shell & Plate Heat Exchanger is applicable for pressures to 103.4 barg [1,500 psig] and at temperatures up to 538 degree C [1,000 degree F] for standard range units. Extended range units are available for higher temperature and pressure applications.

Key Features of Welded Shell & Plate Heat Exchanger

- Extended range units are available for higher temperature and pressure applications. With alternating channels for hot and cold media, it can be configured to provide true countercurrent or co-current flow.

- The chevron-type plates are fabricated into a cassette by a resistance seam weld, whose burst test strength is stronger than parent metal.

- Plate materials may be Type 316L stainless steel, titanium or other alloys; shells may be fabricated of carbon steel, Types 304, 316, 316L stainless and titanium.