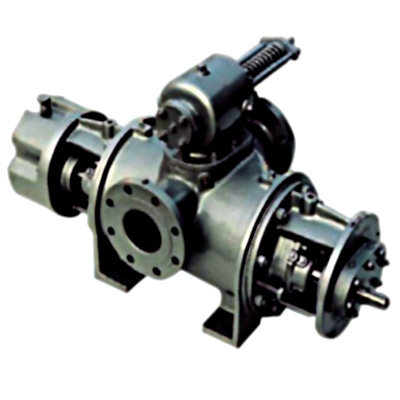

Product Profile of Twin Screw Pumps

Roto Pumps Ltd. offers Twin Screw Pumps. The working principle of Roto Twin Screw Pumps is dependent on the rotation of two screw spindles in closed compartment. A pre-defined clearance is maintained between the screw spindles and between screws and the bore of the casing. When the timed screws start rotating, the liquid is drawn towards the end of the screw spindles and entrapped between the bore of the pumping compartment as well as the flanks of the screws and is then propelled axially from both the ends towards the centre.

Features and Benefits of Twin screw Pumping Principle are:

Long and trouble-free service life

Due to absence of metal-to-metal contact between the pumping elements. Can even run dry for limited period of time

No axial thrust

Dual flow of liquid in opposite direction balances axial thrust

Higher volumetric efficiency

Due to special double profile of screw flanks

High cavitation free suction lift

Due to low NPSH [R]

Self-priming and capable of handling entrapped air/vapour/gas

Due to positive displacement action and being inherently self-priming

Uniform metered flow

Being a positive displacement pump, head developed is independent of speed and capacity is approximately proportional to speed

Capable of handling wide variety of Fluids

Lubricating/non-lubricating as well as aggressive liquids can be handled due to choice of different designs and material of construction

Safe to operate

Has in-built relief valve designed to bypass upto 100% capacity

These pumps find application in the various industries:

Oil & Gas

Sugar

Power Plant

Man Made

Fiber

Marine

Paper

Steel

Fertilizers

Distillation Plant

Edible Oil