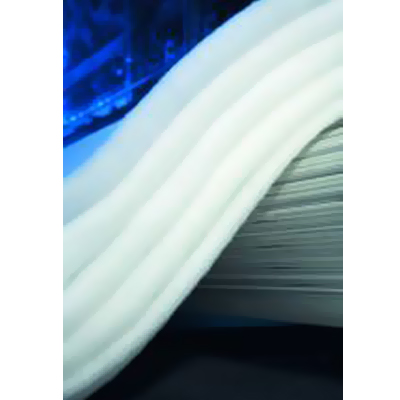

Product Profile of Three Dimensional Non Woven Abrasives

R. R. International supplies Three Dimensional Non Woven Abrasives. R. R. International is an ISO 9001: 2000 certified company. The Three Dimensional Non Woven Abrasives are available in various forms such as Rolls, Hand Pads, Belts and Wheels.

Key Features of Three Dimensional Non Woven Abrasives

- Nylon Fibres impregnated with abrasive grains held together by resin to form loose webbing.

- Designed to provide the operator with a controlled & sustained stock removal and finish.

- Provides a consistent finish.

- The spring like construction of Non Woven Abrasive greatly reduces the risk of gouging & under cutting of the work piece.

- Non Woven Abrasive Wheels are designed for use with air & electric hand tool as well as small bench grinder.

- Provides a resilient backing that eliminates the layover effect encountered with conventional abrasives flap wheel.

- Interleaved flap wheels generate a deep uniformed scratch pattern

- Non Woven Abrasive belts are used for surface conditioning.

- Materials: Aluminium Oxide, Silicon Carbide [Black]

- Grit: Coarse, Medium, Fine, Very Fine.

- Deburring: Removing exit burrs, weld splatters, die cast flash & parting lines.

- Blending: Mill & Tools marks & uneven edges.

- Cleaning: Corrosion, Paints, Coatings & Rust.