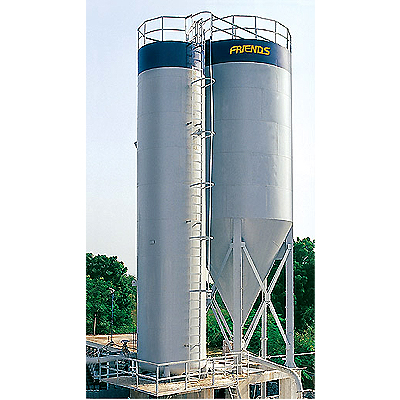

Product Profile of Steel Fabricated Water Sedimentation Tank

Friends Engineering Works supplies Steel Fabricated Water Sedimentation Tank. Friends Engineering Works manufactures a wide range of machines used in Marble Quarrying, Processing and Finishing activities. The Steel Fabricated Water Sedimentation Tank ensures crystal clear filtration and re-cycling of water which is mixed with marble slurry, hence, keeping the environment pollution free.

Key Features of Steel Fabricated Water Sedimentation Tank

- Supply of clean water to the machines enhances fast cutting of stone as well as more production and tool life.

- Collection of slurry mixed water from the machine in an underground tank.

- Water is chemically treated by injecting chemical through dozing pump for separation of water from slurry.

- Chemically treated water is pumped through a battery of heavy duty slurry pump to conical tank.

- Slurry settles down in the cone of tank and clear water over flows in another tank.

- The deposited slurry in conical tank is removed through a heavy duty sluice value.