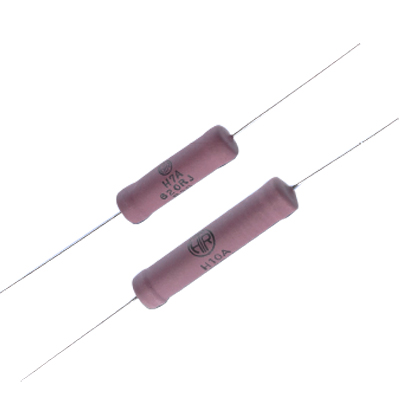

Product Profile of Silicone / Cement Coated Wire Wound Resistors

Hi-tech Resistors Pvt. Ltd. manufactures Silicone / Cement Coated Wire Wound Resistors. Hi-tech Resistors Pvt. Ltd. is an ISO 9001:2000 certified company. Silicone / Cement Coated Wire Wound Resistors has flame retardant coating compatible with Underwriters Laboratories standards 0.5 W to 20 W. This resistor has tolerances as close as 0.25%.

Silicone / Cement Coated Wire Wound Resistors have the following features:

R 01 to 120 K

TCR as low as +20ppm/°C available depending on application and resistance value

Special types available for pulse applications-IEC 61000-4-5