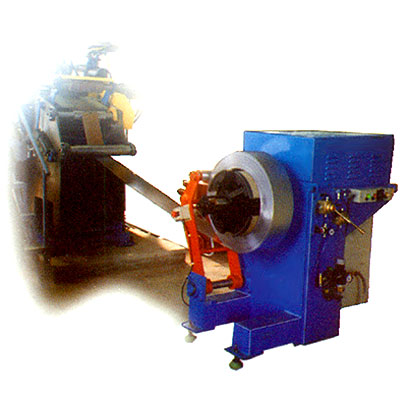

Product Profile of Precision Tension Winder for Strip Casting Machines

Precision Tension Winder for Strip Casting Machines is available with Rigid Fabricated Structure. Press Room Automation & Feed Fixtures [I] Pvt. Ltd is the manufacturer of Precision Tension Winder for Strip Casting Machines. Press Room Automation & Feed Fixtures [I] Pvt. Ltd also manufactures various types of pneumatic feeder / air feeder, mechanical roll feeder, mechanical gripper feeder, NC servo roll feeder, NC straightened feeder, Zig- Zag feeder, coil stock lubrication system etc. Precision Tension Winder for Strip Casting Machines comes with three / four self centering coil-location jaws.This Precision Tension Winder is available with control panel with which a loop control system is attached to maintain loop of coil for the machine via antenna type loop sensors / limit arm through limit switches / photo sensors.

Key Features of Precision Tension Winder for Strip Casting Machines

- Rigid Fabricated Structure.

- Three / Four Self Centering Coil-location jaws With mechanical gear reducer for models above 2.5 Ton

- The Spindle & Coil holding heads housed in mechanical & precise machined housing & rotates on dust proofed sealed bearing element.

- All motorized decoilers are chain driven soft start & stop through mechanical torque limiter & friction drag brake.

- Drive System : A.C. Fixed Speed /A.C. Variable Speed [optional]

- Control Panel with Suitable loop control system to maintain loop of coil for the machine via Antenna Type loop sensors / limit arm through limit Switches / Photo sensors

- In Twin Spindle Decoilers, two mandrels are housed on a Turret and Turret is supported on antifriction bearings for reducing friction while indexing.

- Turret is locked by spring loaded plunger & released by foot pedal