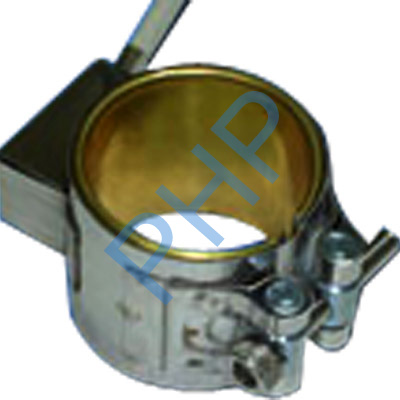

Product Profile of Mica Nozzle Heaters

PHP Mica Nozzle Heaters are designed and manufactured with more than 40 years of

practical experience, for superior performance and life expectancy. As a manufacturer specialized in industrial electric heating elements & the desire to provide quality

products and services to our customers both OEM`s & End Users, PHP specializes in designing Mica Nozzle Heaters, Ceramic Band Heaters, Mica Band Heaters, & Strip

Heaters to your exact specifications. Depending upon applications PHP Nozzle Heaters are manufactured with high temperature oxidation metal sheath and high grade mica insulation resistant to moisture and high temperatures. A superior grade NiCr resistance wire is evenly wound to provide uniform and reliable heat distribution with the best

combination of physical strength, high emissivity & good thermal conductivity to heat machine nozzles, good for sheath temperature up to 300°C. PHP Nozzle Heaters are

also available with various construction styles with special inbuilt Energy saving options.

Key Features of Mica Nozzle Heaters

- Chrome Nickel Steel clamping with MS Inner Sleeve.

- 500 mm Glass Fibre insulated Cable

- Terminal Protection Cap, unless specified.

- Single Piece Construction.

- Clamping: Barrel Nut type.

- Chrome Nickel Steel clamping with Chrome Nickel Steel inner Sleeve.

- Terminal Protection Cap, unless specified.

- Single Piece Construction.

- 500 mm Glass Fibre insulated Metal Braided Cable.

- Clamping: Barrel Nut type.

- Chrome Nickel Steel clamping with Brass/Chrome Nickel Steel inner Sleeve.

- Energy Saving Insulated Cover.

- Barrel Nut type clamping with Terminal Protection Cap, unless specified.

- 500 mm Glass Fibre insulated Metal Braided Cable.

- Single Piece Construction.

- Single Phase: PHP`s band heaters are usually designed on 230 Volts single phase unless specified.

- Dual Phase: Mica Nozzle Heaters can be designed with multiple circuits to operate in single or dual-phase circuits