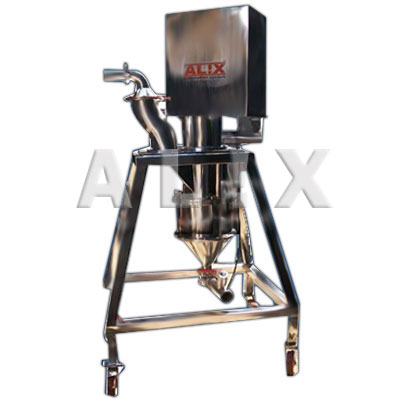

Product Profile of Inline Multi Mill With Cylindrical Screen

Inline Multi Mill with Cylindrical Screen is suitable for high speed granulating, pulverising, mixing, shredding, and chopping of wet and dry products. The Inline Multi Mill is designed for continuous operation and is suitable for manual or inline milling through pneumatic conveying system. The Inline Multi Mill has all contact parts made of stainless steel 316 and non-contact parts are made of stainless steel 304. Inline Multi Mill with Cylindrical Screen is used in various industries like pharmaceuticals, chemicals, cosmetics, food product, ceramics, dyestuff etc.

Alix Automation System manufactures Inline Multi Mill with Cylindrical Screen. Alix Automation System offers wide range of mechanical pneumatic material handling and ingredient processing systems like tablet press loader, inline sifter, in-line feeder vessel and co-mill for pharmaceutical, food, beverages, chemical and paint industries.

Applications of Inline Multi Mill with Cylindrical Screen:

High speed granulating, pulverising, mixing, shredding, and chopping of wet and dry products

Pharmaceuticals

Chemicals

Cosmetics

Food product

Ceramics

Dyestuff

Key Features of Inline Multi Mill With Cylindrical Screen

- Used for high speed granulating, pulverising, mixing, shredding and chopping etc.

- Used as an inline attachment of vacuum conveying also

- Utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control reduction

- All contact parts stainless steel 316 and non-contact parts stainless steel 304

- Suitable for manual or inline milling through pneumatic conveying system

- Various combination of screens, speeds, number of blades or direction of rotation of blades, can be selected

- All components can easily be dismantled and cleaned for change of product.

- Wide range of stainless steel perforated and wire knitted screen available

- Dust free operation

- Cylindrical Screen for higher output