Product Profile of Fiber Bed Mist Eliminator

Fiber Bed Mist Eliminator is a continuous duty collector that can effectively control mist and smoke from various manufacturing processes. The Mist Eliminator is designed to be 99. 5% efficient for mist and smoke and with the unit is 99. 97% efficient at 0. 3 microns. The Mist Eliminator is widely used in plants of sulphuric acid, phosphoric acid, caustic chlorine units, hydrochloric acid, fluorine units and nitric acid. Fiber Bed Mist Eliminator is provided with a pre-filter section to protect main filters and blower inside housing for quieter operation.

Applications of Fiber Bed Mist Eliminator:

Sulphuric acid plant

Phosphoric acid plant

Caustic chlorine units

Hydrochloric acid plant

Fluorine units

Nitric acid plant

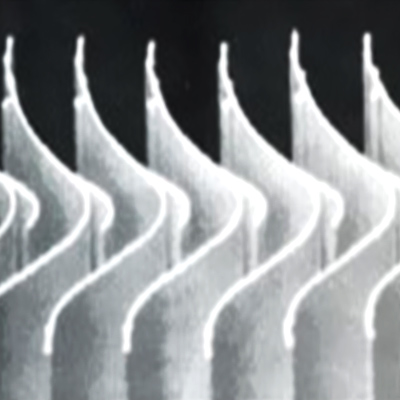

Key Features of Fiber Bed Mist Eliminator

- A continuous duty collector that can effectively control mist and smoke from various manufacturing processes

- Designed to be 99. 5% efficient for mist and smoke and with the unit is 99. 97% efficient at 0. 3 micron

- Provided with a pre-filter section to protect main filters, blower inside housing for quieter operation

- 10 gauge heavy duty construction

- Easy to read pressure gauges

- Hinged doors for easy access

- Small filter footprint for ease of handling

- Blower discharge from either top or side of unit for easy installation

- Used to control stack emissions to the atmosphere

- Eliminate or reduce damage of equipment caused by corrosive or fouling liquid droplets

- Recover valuable liquids