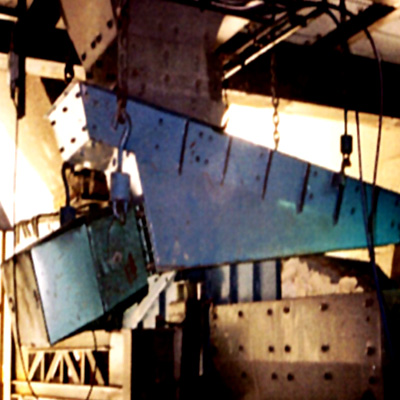

Product Profile of Dust-Tight Spring-Connected Electromagnetic Vibrating Feeder

Electro Magnetic Flux Industries supplies Dust-Tight Spring-Connected Electromagnetic Vibrating Feeder. Electro Magnetic Flux Industries offers various types of vibrating and magnetic equipment etc. Dust-Tight Spring-Connected Electromagnetic Vibrating Feeder is applicable in a wide range of operations in the food, mining, cement, refractory, iron ore, coal feeding, feed, and chemical and the pharmaceutical industries. This Electromagnetic Vibrating Feeder comes with bolt-in replacement option through liners.

Key Features of Dust-Tight Spring-Connected Electromagnetic Vibrating Feeder

- Dust-tight and maintenance-free drive units

- Above- or below-deck drive units

- Two-mass, spring-connected, sub-resonant tuned

- High frequency - 3600 VPM at 60Hz

- Stroke - 0.060 inches

- Stroke generated by creating a magnetic field

- Suspension mount, base mount or combination of both

- Bolt-in replacement trough liners

- Multiple-drive unit feeders available

- Flow-extraction from silo / hopper

- Flow-regulation for weighing equipment etc.

- Flow-feeding for / in process lines