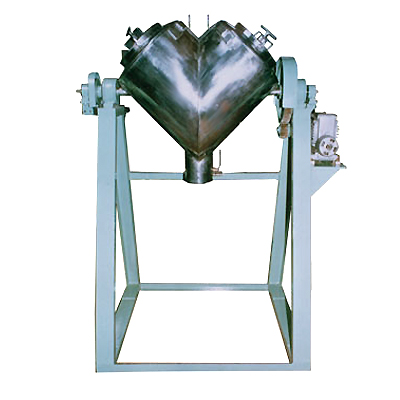

Product Profile of Industrial Grade "V" Blender

Industrial Grade "V" Blender can be used for dry blending or with added features for incorporating liquid ingredients into powders and even for effecting drying. The Blender can be available form laboratory models of 5 litres to production models of 10, 000 litres capacity. The Blender has a container which is provided with closures on which are provided quick opening covers. The Industrial Grade "V" Blender has a discharge nozzle that can be used for feeding the material to be processed in case of larger blenders.

Traxit Engineers Pvt. Ltd manufactures Industrial Grade "V" Blender. Traxit Engineers Pvt. Ltd is the supplier of a wide range of process machineries for application in various industrial sectors. The range of products includes double planetary mixer, vertical rotary airlocks, contra mixers etc.

Application of Industrial Grade "V" Blender:

Pharmaceutical

Metal powder

Chemical

Food

Plastic

Soap and detergent

Agro chemical

Ceramic

Cosmetic

Key Features of Industrial Grade "V" Blender

- Can be available form laboratory models of 5 litres to production models of 10, 000 litres capacity

- Has a container which is provided with closures on which are provided quick opening covers

- Discharge nozzle that can also be used for feeding the material to be processed in case of larger blenders.

- The product being processed is rotated close to the axis of rotation and hence the power required is low without affecting the mixing efficiency.

- The unit has two large openings so the interior is readily accessible for cleaning.