Product Profile of Condensate Polishing Unit

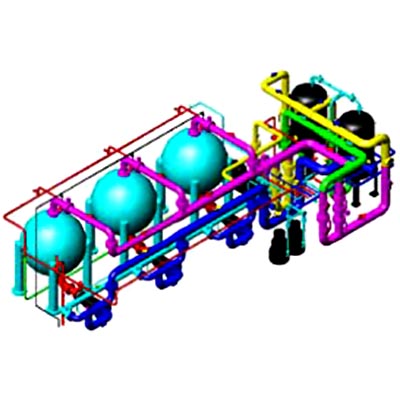

Triveni Engineering & Industries Ltd offers Condensate Polishing Unit. Triveni Engineering & Industries Ltd is ISO 9000-2000 and ISO 14001 certified. Condensate Polishing Unit is used for the treatment of condensed steam from turbines by resin based technology in the power sector & other industrial applications including refineries. The Condensate Polishing Unit [CPU] consists of a Deep Mixed Bed Service Vessel with external regeneration system. Condensate Polishing Unit adopts advanced "High vessel separation & external regeneration technology", which has the following features:

Unique structure of collector at the bottom of the Service vessel - Mixed Bed, which ensures resin transfer rate of more than 99.99 &permil.

Unique design of the regeneration device avoids flow concentrations and ensure stable resin interface.

Sound interface detection device ensures high resin separation rate.

Long operation cycle for selected mode.

Advantages of Condensate Polishing Units:

Start / Restart times of the high pressure boiler may be excessive without treating the boiler feed water to get high purity and this could result in excessive blow-downs plus high replacement power costs during extended start ups

A CPU system continuously removes contaminants like silica, iron oxides, chlorides, sodium, & suspended curd, etc present in the return condensate, thereby improving the operating efficiency and minimizing the corrosion rate

A CPU system also provides protection during condensate leaks. CPU allows the unit to remain in service until the leak is repaired or by planning an orderly shutdown than a full load trip