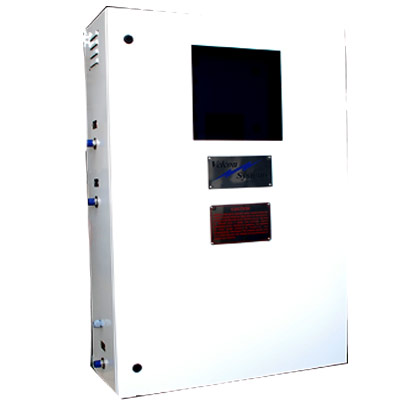

Product Profile of Compact Designed Ultrafiltration Plants

Compact Designed Ultrafiltration Plants employ a robust membrane fibre that ensures long term integrity. The Ultrafiltration Plants are available in pressurized or submerged configurations suitable for multiple plant requirements. The Ultrafiltration Plants possess optimum fibre strength and are easy to install. The Compact Designed Ultrafiltration Plants ensure effective pathogen removal.

Application of the Compact Designed Ultrafiltration Plants:

Dialysis and other blood treatments

Concentration of milk before making cheese

Fractionation of proteins

Clarification of fruit juice

Recovery of vaccines and antibiotics from fermentation broth

Laboratory grade water purification

Wastewater treatment

Drinking water disinfection [including removal of viruses]

Removal of endocrines and pesticides combined with suspended activated carbon pre-treatment

Apple juice and wine can be clarified

Waste treatment and product recovery is possible in edible oil, fat, potato, and fish processing

Fermentation broths can be clarified and separated

Whole egg and egg white ultrafiltration as a preconcentration prior to spray drying

Industrial applications include power generation

Food and beverage processing

Semiconductor manufacturing

In industry to separate suspended solids from solution

Key Features of Compact Designed Ultrafiltration Plants

- Employ a robust membrane fibre that ensures long term integrity

- Available in pressurized or submerged configurations suitable for multiple plant requirements

- Possess optimum fibre strength and are easy to install

- Ensure effective pathogen removal

- Stand-alone pre-packaged units and components for larger projects have been designed to be assembled in the factory

- Consistent water quality from any source water

- Compact design resulting in small system footprint