Product Profile of Ceramic Fiber Shapes Papers

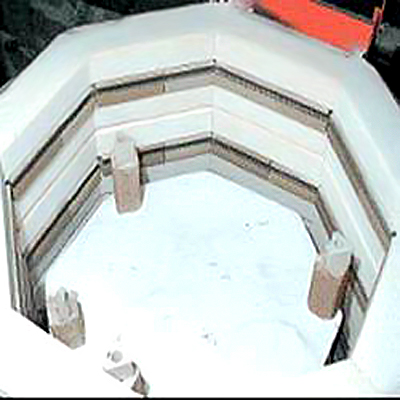

The Ceramic Fiber Shapes Papers comes with outstanding thermal and physical characteristics. These are manufactured from alumina-silica fibers in a vacuum forming process with a latex binder system. In the manufacturing process, high purity washed fibers which have been cleansed of most unfiberized particles are randomly oriented to form a uniform, flexible, lightweight paper. Bharathi Refractory Technologies manufactures Ceramic Fiber Shapes Papers.

Bharathi Refractory Technologies supplies Castables and Mortar, Acid Proof Mortars, Element Supports, Insulation Bricks, Precast Prefired Shapes, Fire Clay and Ceramic Fiber Papers.

The Ceramic Fiber Shapes Papers high temperature performance properties ideal for most refractory-type applications, including:

Industrial furnaces, steel ladles, casting barrels and submerged nozzles

Heat shielding

Wood burning stoves

Electric and thermal insulation for electric furnaces

Sealing for furnace doors and expansion joints

Lining for aluminium casting moulds

Burner gaskets

Thermal and electric insulation for heaters

Acoustic and thermal insulation for automobile mufflers

Heat insulation for exhaust tubes and pipes

Refractory back-up

Sizes of the Ceramic Fiber Shapes Papers are:

Thickness: 1mm to 10mm

Width: 500 to 1000 mm

Length: 1000 mm to 1200 mm

Shapes: as per customer drawing & requirements.

Color: white

Density : minimum 200 kg/cubic m