Product Profile of Brass made Internal Gears

Zenith Engineers manufactures Brass made Internal Gears. The high quality Brass made Internal Gears encompasses cylindrical pith surface that has teeth parallel to the axis and forms excellent tools used to design solid models of drive components. Internal Gears are hollow and feature teeth cut on the inner side of the rim rather than outside.

Zenith Engineers is the supplier of Bevel Gear, Bolster Machining, CNC Turning Centre, Helical / Double Helical Gears, Internal Gears, Rack And Pinions, Spur Gears, etc. The Brass made Internal Gears are quite similar to the External Gears in the terms of properties and teeth shape, but in order to prevent interference in internal meshes, these have different and modified addendum & dedendum values. The specific non-binding tooth design of Internal Gears, suits almost all kinds of equipment, and ensures smooth & quiet operation.

Salient characteristics of Brass made Internal Gears are:

Internal Gears up to 12 Module 1500 mm

ID can be done

Available only in brass

Offers low sliding and high stress loading

To produce large reduction ratios, these are used in planetary Gears

The teeth in the Gears are cut into the inside diameter while the outside diameter remains smooth

The difference between the number of teeth of girth gear and the pinion should not be less than 15, while choosing a mating gear

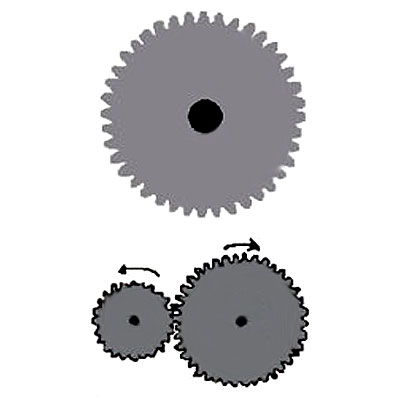

Used to transmit rotary motion between parallel shafts that are rotating in the direction of the arrangement

Widely used in applications such as rollers, indexing, timing and other light duty applications