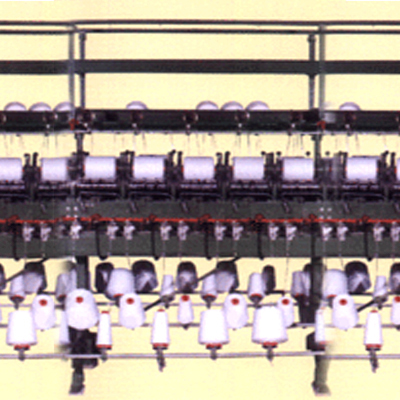

Product Profile of Assembly Winder Machine

Harish Tex-Mach Pvt. Ltd offers Assembly Winder Machine. Harish Tex-Mach Pvt. Ltd supplies Fabric Processing Machines like stenter, jigger, relax dryer etc. The Assembly Winder Machine is designed to assemble 4 ends on to a cheese with 0 ° 0` conicity and is suitable for feeding Two or One Twister, Doublers and Ring Twisting Frames with desired unwinding characteristics.

Key Features of Assembly Winder Machine

- Rigidly constructed to attain highest mechanical speed up to 800 Meters/Min. with smooth functioning and appreciably no vibration.

- Double arm packages are mounted with suitable adaptors and precision high speed bearings to produce packages of 0°0` conicity with 6" Traverse length.

- Electro-mechanical stop motion to stop the spindle immediately upon breakage of one end.

- A brake shovel helps to lift the package from constant rubbing on the drum.

- The split end preventer minimizes split ends and prevents loop formation at twisting stage by compensating the tension of individual ends.

- An electronic anti-patterning device minimizes ribbon formation or overlapping of yarn and also ensures the uniform density of the package.

- Produce Package storage tray on full length of the machine is mounted above the machine.

- 2 Nos. 7.5 HP 1440 RPM Foot mounted Motors suitable for 3 Phase 400/440 Volts.

- One set of interchangeable driver and driven pulleys for required winding speeds.