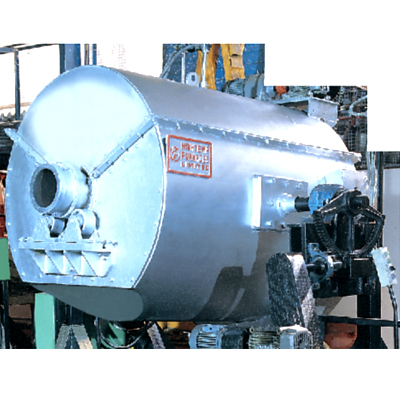

Product Profile of Annealing, Normalizing And Sintering Conveyor Furnaces

Dynatech Furnaces, since 1985, manufactures various types of Production vacuum and atmosphere furnaces. Being a part of that Sintering Conveyor Furnaces is used for auto component and engineering heat treatment requirement. Key-features of this furnace are as follows:

Standardized models for various component dimensions and weights

Furnaces designed for use up to 1,150 C in atmosphere

Atmosphere of dissociated ammonia, endo gas, exo gas, nitrogen etc.

Continuous automatic operating treatment line with integral Fast Cool Turbo system from entry to exit

Fuel fired system - LPG gas fired and Oil Fired as desired & Electric Resistance Type

Unique heater design [in electric resistance option] to ensure heaters operate at low voltage and thus provide extended heater life and also enable ease in heater replacement, without shutting of furnace line

Very low mass fiber insulation with unique module approach

Specialized turbo cooling systems, in line, for control and rapid cooling rates using indirect water-cooling closed loop system

Profiling temperature survey facility along furnace length

Large range in variation of conveyor belt speed for adjustment of cycle time

Conveyor Belt design ensures longer belt life with lower belt stresses

Systems can be offered with metallic muffle [with unique sole design to minimize muffle distortion and extend muffle life]